No products in the cart.

Uncategorized

The Science Behind the Wash Effect: How It’s Made

The wash effect, often seen on denim and various fabrics, is a popular treatment that gives garments a unique look and feel. While it may appear to be a simple finishing touch, the science behind the wash effect is complex and involves various processes and techniques. In this article, we’ll delve into the science behind the wash effect, explore the methods used to create it, and discuss its significance in fashion. Whether you are a fashion enthusiast or a curious consumer, understanding this process adds depth to your appreciation of the clothing you wear.

What is the Wash Effect?

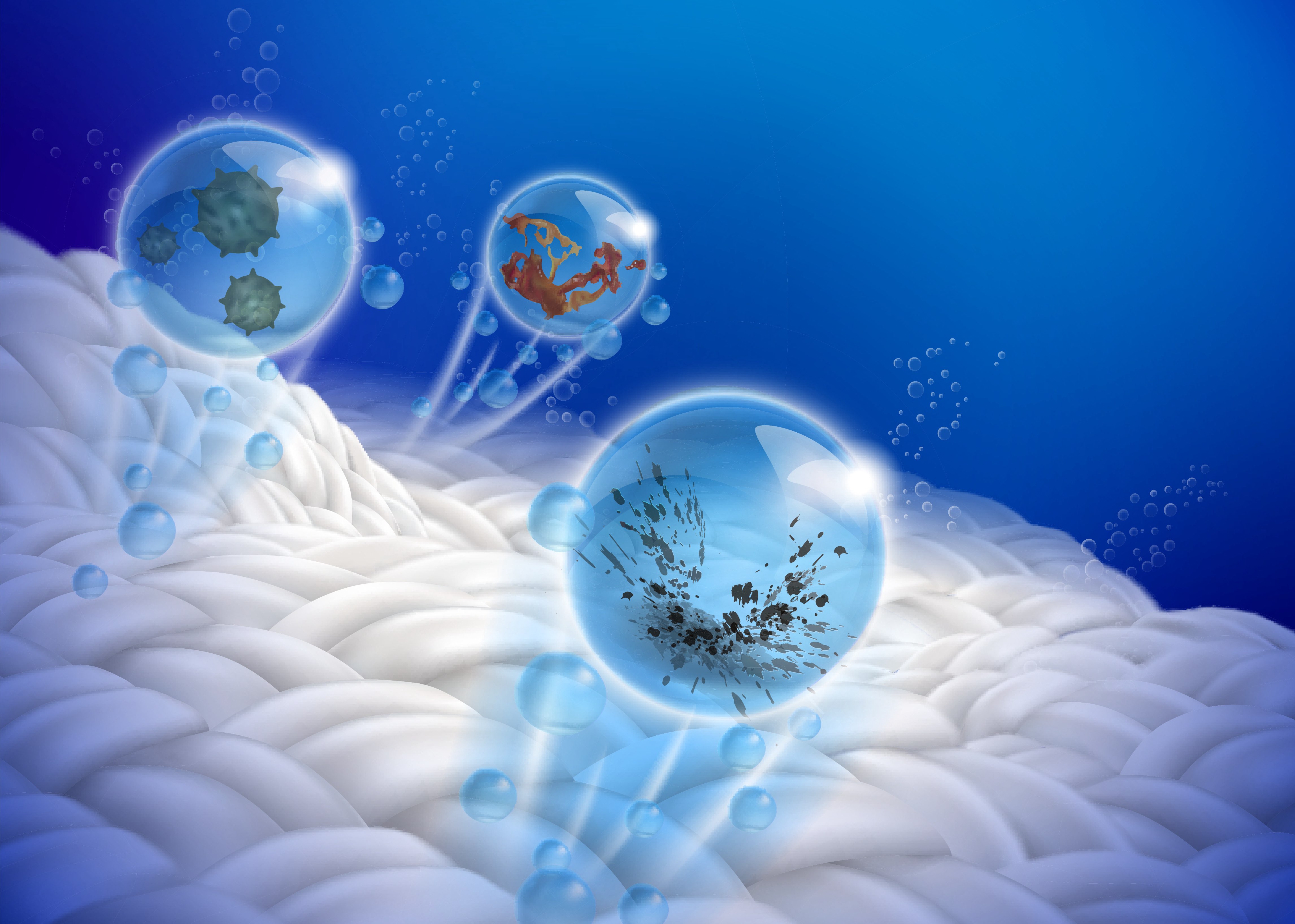

The wash effect refers to the visual and tactile characteristics imparted to fabrics, particularly denim, through specific washing and treatment processes. This effect can range from a subtle fade to a heavily distressed appearance, enhancing the fabric’s texture, comfort, and aesthetic appeal. The wash effect is achieved through various methods, including stone washing, enzyme washing, and acid washing.

Understanding the Materials

Before we dive into the processes, it’s essential to understand the materials involved. Most garments that undergo the wash effect are made from cotton or cotton blends. Cotton is a biodegradable, natural fiber known for its softness, breathability, and comfort. Denim, a sturdy cotton twill fabric, is particularly popular for the wash effect due to its versatility and durability.

Different Types of Fabrics

- Denim: A robust fabric that can withstand harsh treatment, making it ideal for various wash effects.

- Cotton: Soft and breathable, often used for t-shirts and casual wear.

- Cotton Blends: Combining cotton with synthetic fibers to enhance durability and reduce wrinkling.

The Processes Behind the Wash Effect

- Stone Washing

Stone washing is one of the oldest methods used to create the wash effect. This process involves washing denim garments with large stones, typically pumice, to create a faded appearance.

How it Works:

- The stones are added to industrial washing machines along with water and detergent.

- As the machine operates, the stones tumble against the fabric, causing abrasion and fading.

- The result is a softer, worn-in look that mimics years of wear.

Advantages:

- Softens the fabric, enhancing comfort.

- Creates a unique, vintage appearance that is highly sought after.

Disadvantages:

- Environmental concerns due to water usage and the disposal of stones.

- Enzyme Washing

Enzyme washing is a more modern and eco-friendly method that employs enzymes to achieve the wash effect. This technique is particularly popular for its ability to create a soft feel while minimizing environmental impact.

How it Works:

- Enzymes, such as cellulase, are added to the wash cycle.

- These enzymes break down cellulose fibers in the cotton fabric, leading to a faded appearance and a softer texture.

- The process can be controlled to achieve varying levels of fading.

Advantages:

- Reduces water consumption compared to traditional methods.

- Produces consistent results with minimal environmental impact.

Disadvantages:

- Requires precise control to avoid over-processing.

- Acid Washing

Acid washing involves treating fabric with a bleaching agent, usually potassium permanganate, to create a dramatic contrast in color. This method is often used to achieve a high-contrast, distressed look.

How it Works:

- Garments are soaked in a bleach solution that selectively removes color, creating a mottled effect.

- The process can be combined with other treatments (like stone washing) for a more complex appearance.

Advantages:

- Allows for creative designs and unique patterns.

- Produces a striking visual impact.

Disadvantages:

- Can weaken the fabric due to the harsh chemicals used.

- Whiskering and Hand Sanding

To complement the wash effect, many manufacturers use whiskering and hand sanding techniques. These methods enhance the overall look by adding subtle details.

How it Works:

- Whiskering: Involves creating fine lines or ‘whiskers’ around pockets and seams to simulate wear.

- Hand Sanding: This manual process involves using sandpaper to selectively fade areas of the fabric.

Advantages:

- Adds character and authenticity to the garment.

- Allows for customization and unique designs.

Disadvantages:

- Labor-intensive and time-consuming processes.

Environmental Considerations

The fashion industry has faced scrutiny regarding its environmental impact, particularly concerning water usage and chemical treatments. Fortunately, advances in technology and a growing focus on sustainability have led to more eco-friendly alternatives for achieving the wash effect.

Sustainable Practices

- Waterless Dyeing: Innovations in dyeing technology reduce water usage significantly.

- Biodegradable Enzymes# The Science Behind the Wash Effect: Unraveling the Secrets of Denim Distressing

Introduction: The Allure of the Wash Effect

The iconic “wash effect” on denim has captured the imagination of fashion enthusiasts and casual wearers alike. From the subtle fading to the intricate patterns of whiskering and distressing, this unique aesthetic has become a hallmark of modern denim design. But have you ever wondered what goes on behind the scenes to create this sought-after look? In this comprehensive guide, we’ll delve into the science and technology that transforms raw denim into the stylishly worn-in pieces we love.

Understanding the Denim Fabric

To fully appreciate the wash effect, it’s crucial to understand the composition and structure of denim fabric. Denim is a sturdy cotton twill textile, characterized by its distinct diagonal ribbing pattern. The warp threads, which run lengthwise, are typically dyed with indigo, while the weft threads that run crosswise are left undyed, creating the iconic blue-and-white appearance.

The Wash Effect: A Multifaceted Transformation

The wash effect is the result of a carefully orchestrated series of mechanical and chemical processes that work together to create the desired distressed look. Let’s explore the key steps involved:

- Pre-treatment and Sizing Removal

The first step in the wash effect process is to remove the sizing, a starch-based coating applied to the fabric during production to stiffen and protect the fibers. This is typically done through a combination of enzyme treatments and washing, which help break down and remove the sizing, allowing the fabric to become more pliable and receptive to the subsequent steps.

- Stone Washing

One of the most iconic techniques in creating the wash effect is stone washing. This process involves tumbling the denim with pumice stones, which act as an abrasive to create localized fading and whiskering patterns. The stones rub against the fabric, gradually wearing down the indigo dye and creating a unique, vintage-inspired look.

- Enzyme Washing

Enzymes play a crucial role in the wash effect process. Specific enzymes, such as cellulases, are used to selectively break down the cotton fibers, particularly in high-friction areas like the knees and elbows. This targeted degradation results in a more pronounced faded and distressed appearance, mimicking the natural wear and tear that occurs over time.

- Laser Distressing

In recent years, the use of laser technology has revolutionized the denim industry. Laser machines can precisely target specific areas of the fabric, burning away the indigo dye to create intricate patterns of rips, holes, and abrasions. This technique allows for a high degree of control and consistency, enabling designers to achieve unique and customized wash effects.

- Manual Finishing Touches

While the previous steps lay the foundation for the wash effect, skilled artisans often add the final touches by hand. This can include techniques like sanding, grinding, and even hand-tearing the fabric to create a truly one-of-a-kind, artisanal look.

The Science Behind the Wash Effect

The science behind the wash effect is a fascinating interplay of materials, chemistry, and engineering. From the molecular structure of the cotton fibers to the physics of abrasion, each step in the process is carefully calibrated to achieve the desired aesthetic.

Fiber Structure and Dye Interactions

The indigo dye used to color denim is a complex molecule that binds to the cotton fibers in a unique way. As the fabric is subjected to various washing and distressing techniques, the dye-fiber interactions are disrupted, leading to the gradual fading and exposure of the undyed white weft threads.

Mechanical Abrasion and Fiber Degradation

The physical processes involved in stone washing, enzyme treatment, and laser distressing all work to systematically break down the cotton fibers. This controlled degradation creates the worn, textured appearance that is the hallmark of the wash effect.

Precision and Customization

The use of advanced technologies, such as laser cutting and computer-controlled stone washing, allows for an unprecedented level of precision and customization in the wash effect process. Designers can now create highly intricate and personalized distressed patterns, catering to the ever-evolving demands of the fashion industry.

The Sustainability Factor

As consumers become more conscious of the environmental impact of the fashion industry, the wash effect has also come under scrutiny. Traditional methods, such as stone washing, can be resource-intensive and generate significant amounts of wastewater. However, the industry is actively exploring more sustainable alternatives, such as ozone washing and laser technology, which can reduce water usage and chemical consumption while still delivering the desired aesthetic.

Conclusion: The Lasting Appeal of the Wash Effect

The wash effect has become a cultural icon, transcending the boundaries of fashion and capturing the imagination of consumers worldwide. By understanding the science and technology behind this captivating aesthetic, we can appreciate the skill, innovation, and attention to detail that goes into creating these unique and coveted denim pieces. As the industry continues to evolve, the wash effect will undoubtedly remain a beloved and enduring part of the denim landscape.